Protecting against lithium-ion battery fires

Early fire detection for the waste management sector via temperature monitoring

Lithium batteries as fire hazards in recycling facilities

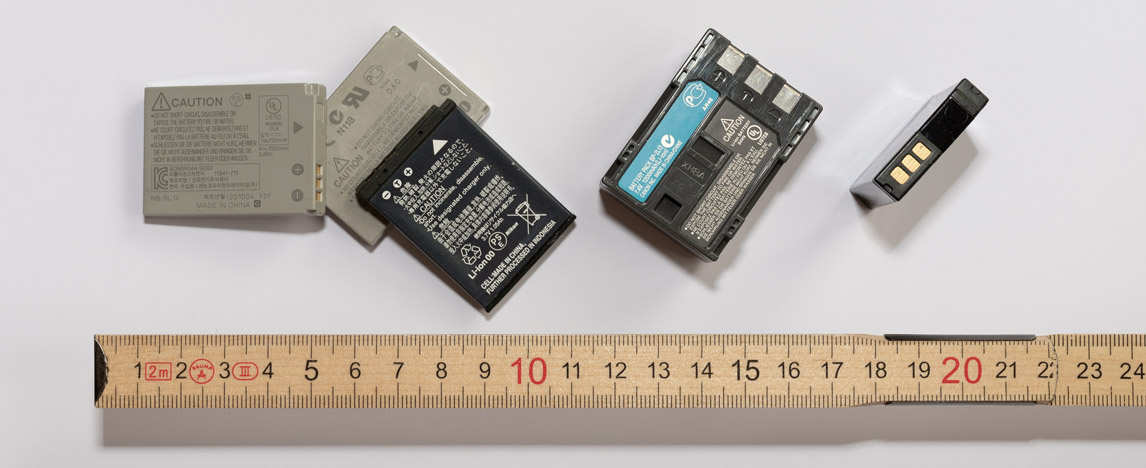

Why are incorrectly disposed batteries and rechargeables so dangerous?

For recycling operators, lithium-ion batteries have become the No. 1 fire hazard. Lithium batteries that have not been disposed of correctly are causing fires in waste management facilities on an almost weekly basis. Any batteries not detected during sorting become unpredictable fire hazards at every stage in the processing chain.

- Pressure and high temperatures in the refuse collection vehicle can already damage the linings around Li-ion batteries. This can result in short circuiting, overheating and spontaneous ignition.

- When the damaged batteries are dumped and moved around, they come into contact with oxygen. Fires can then develop.

High energy density makes even small batteries and rechargeables potential fire sources with high fire loads.

- Damaged batteries can self-ignite within hours, days or weeks.

- When batteries go through shredders, mechanical destruction can result in overheating or spontaneous combustion.

- Crushed, overheated battery parts may cool down naturally, but chemical processes are often triggered leading to further heating and eventual ignition.

Solution: Wide-coverage early fire detection using thermal image temperature monitoring

Lithium batteries – fire protection via smart thermal cameras

Thermal cameras (thermal imaging cameras / infrared cameras) can “see” heat and display it pictorially as thermography. Spontaneous ignition of damaged batteries is often preceded by overheating. Thermal imaging temperature monitoring is therefore ideal for protecting against lithium-ion battery fires. However, only a few systems are able to fully meet the high demands of early fire detection in the waste management sector. For example, no false alarms from normally high temperatures in daily operations (e.g. from wheel loaders, etc.). Other demands:

- Small pieces of material move at high speeds along conveyor belts. Detecting even the smallest sources of fire quickly and reliably is vital, especially after shredding.

- Storage sites cover larger areas that need to be fully monitored. Variations in the shape and height of heaped materials must be accounted for.

- When critical temperatures are detected, alarms and automated targeted cooling or extinguishing need to be triggered.

PYROsmart® is an intelligent early fire detection system from Orglmeister. Its key advantage: reliable early detection of critical temperatures and automated pinpoint extinguishing and cooling.

Two application examples can be seen further down this page.

“Please never throw batteries or electronic items containing batteries into the bin!”

Why? See for yourself in this video from SUEZ UK / Aberdeen City Council …

PYROsmart® avoids this – by through early hotspot detection and automatic extinguishing. In more than 500 plants worldwide.

Example 1: Lithium batteries – fire protection via temperature monitoring of free-falling material

PYROsmart® stops the conveyor and controls and manages cooling/extinguishing

When a lithium-ion battery is mechanically shredded, the energy it contains is released. This can lead to instantaneous as well as delayed ignition. Fire can then spread quickly via downstream conveyor belts.

PYROsmart® one is used for monitoring conveyor belt systems. The system can be strategically positioned to monitor free-falling material flows at conveyor transfer points:

- This is where concealed hotspots come into contact with oxygen and increase in temperature.

- Such hotspots can be reliably detected by PYROsmart® thermal image evaluation.

- “Normal” frictional heat generated by shredding subsides by the time the material reaches the next conveyor transfer point. Damaged batteries, however, often continue to heat up.

- These hot battery components are detected by PYROsmart® one as hotspots long before flames appear.

- Thirty individually evaluated infrared images per second mean that reliable monitoring takes place in real time, also at high conveyor speeds. PYROsmart® one is more reliable than any standard IR camera.

- Separate outputs enable the triggering or halting of operations (e.g. stopping the conveyor belt).

- The software enables operation of different extinguishing systems to provide instant fire suppression and fire-fighting.

Lithium battery fire protection: PYROsmart® provides more than other systems by quickly stopping conveyor belts and initiating cooling with water mist nozzles when an alarm is triggered.

Water mist nozzles excel at cooling hotspots on conveyor belts. Fire prevention by prompt cooling is the best way to protect against lithium-ion battery fires.

But what if the battery is already on fire? Conventional extinguishing systems (e.g. sprinklers) are often unable to cope in such cases. Compared with other types of fire, battery fires require instant extinguishing and much larger quantities of water. Burning metallic lithium is particularly difficult to extinguish.

Cooling down both the burning battery and its surroundings is therefore essential and necessary until the reactive process and/or fire within the battery comes to a stop. Water mist systems are ideal for this purpose and prevent further damage from occurring.

Get in contact

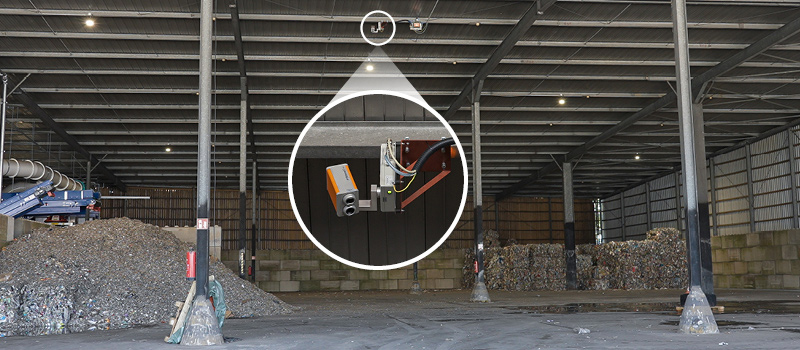

Example 2: Thermal image temperature monitoring for open spaces, premises and storage facilities

Hotspot detection and automatic targeted PYROsmart® extinguishing

Damaged battery cells are susceptible to delayed spontaneous ignition. They therefore not only represent permanent fire hazards when collecting and processing them, but also when storing and moving recycled material. From approx. 70-80°C, a self-reinforcing reaction chain can be set in motion within the battery, which under certain circumstances can lead to an explosive burning of the battery with a persistent flash (“thermal runaway”). Prompt detection of increased surface temperatures is therefore vital.

PYROsmart® pro is used for monitoring large areas, indoor facilities and warehouses. The pan/tilt system uses an infrared thermal camera and video camera. PYROsmart® detects increased surface temperatures and therefore also developing fire hazards. Protective action can then be promptly taken to prevent major damage.

- The pan/tilt system is capable of monitoring much larger areas than fixed IR cameras.

- Hotspots are precisely portrayed as three-dimensional spaces. This enables targeted cooling/extinguishing using fire-monitor extinguishers.

- The infrared camera is equipped with autofocus and is therefore suitable for monitoring material heaps of varying heights and distances.

- A standard-sized, overheated battery can be detected from a distance of 30 m.

- To prevent false alarms from, for example, the hot exhaust pipes of wheel loaders, PYROsmart® pro is equipped with smart recognition of non-hazardous increased temperatures. Standard IR cameras often triggers false alarms and unnecessarily holds up operations. The PYROsmart® pro’s capability of recognizing non-hazardous high temperatures has proven to be highly reliable in practice.

- Clear, patented on-screen thermography portrayals. Option of switching between infrared and video images. Overlapping intermediate stages is also possible.

- Integrated compressed air cleaning keeps the sensors clear. Use in extremely dusty environments is also possible due to the ability of infrared radiation to penetrate such atmospheres.

- VdS-approved (planning and installation according to VdS guideline 3189 / guidelines for camera equipment for temperature monitoring in fire protection).

While other systems only offer detection, PYROsmart® can also control and manage preventive cooling and/or extinguishing of hotspots: automatic, precise and using any standard fire monitor!

Prompt cooling of hotspots and/or prompt extinguishing of developing fires is the best fire protection. PYROsmart® undertakes and manages targeted, automatic extinguishing.

The primary goal is fire prevention by cooling down overheated batteries and surrounding areas. PYROsmart®’s automatic extinguishing enables targeted extinguishing of hotspots. Prompt cooling usually prevents any fires from developing. The system is able to dynamically adapt to actual conditions, e.g., extinguishing window size, water jet setting, etc. Multiple fire monitors can be operated simultaneously.

And what if a battery is burning? Secondary prevention is then the primary aim, i.e., preventing fire from spreading to surrounding combustible recycling material. The ideal option here is also targeted cooling/extinguishing using fire monitors. Sprinkler systems and similar extinguishing technology are unable to provide sufficient supplies of water to the source of fires. Fire monitors, in contrast, apply much larger volumes of water to fire sources very quickly.

PYROsmart® uses temperature measurements to determine the best extinguishing strategy. This ensures batteries and their surroundings undergo continuous extinguishing and cooling. However, if a fire continues to spread despite these actions, PYROsmart® will continue to manage the extinguishing process until the fire-fighting services arrive and take over.

PYROsmart® protects recycling and waste management facilities. Targeted extinguishing leaves unaffected areas intact and reduces operational downtimes and production stoppages.