Thermal image camera monitoring

Thermography is being used in many areas

Fire protection and early fire detection (thermal image camera monitoring)

Fires can start unexpectedly during waste storage at waste incineration and recycling facilities. Fire is also possible at any time when storing fuels for coal, wood and RDF power plants, when storing combustible materials in the open air and in warehouses.

The faster a developing fire is detected, the lower the subsequent damage. Orglmeister Infrarot-Systeme therefore developed the patented PYROsmart® early fire detection system.

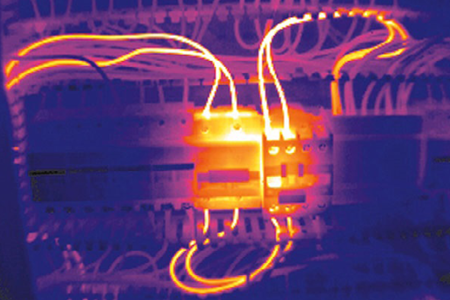

Predictive maintenance

Thermal image camera monitoring (or thermography) enables detection of irregularities, usually invisible to the human eye, and the need for maintenance measures. It can do this during ongoing operation, without any contact required, and before costly system failures or recourse claims occur.

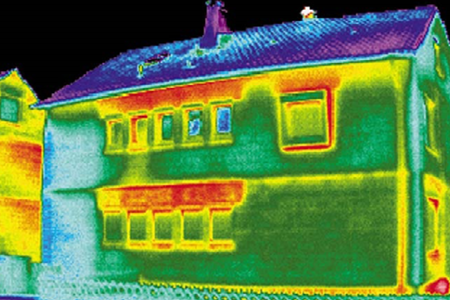

Building thermography

Using a thermal imaging camera enables precise analysis of a building’s thermal weakness. It assists in targeting insulation measures and ultimately in saving energy costs.

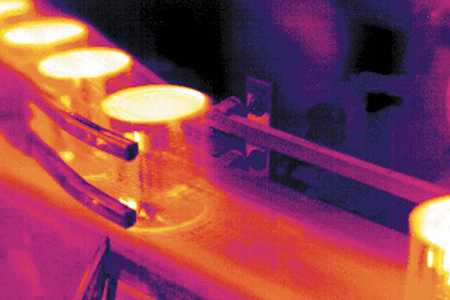

Automation

Thermal imaging cameras enable cost-effective, fully integrated thermography and measurement systems solutions (thermal image camera monitoring) for a wide range of applications, such as process development and optimization, industrial process monitoring, product testing, quality assurance, security applications and fire protection.

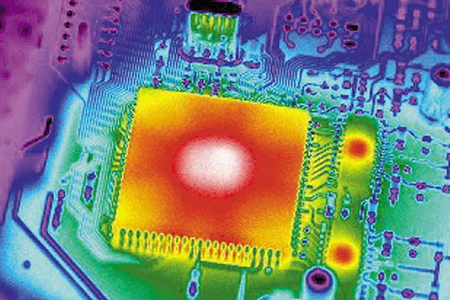

Research and development

Thermal imaging cameras capture and record temperature distributions, also in real time, to aid technicians and engineers in visualizing and quantifying heat distribution in equipment and processes.

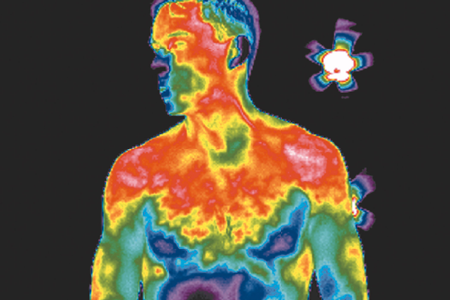

Human medicine and veterinary medicine

Powerful infrared cameras are used as highly sensitive diagnostic tools for a wide range of clinical and experimental applications, from breast cancer screening to open heart surgery. Detecting inflammations and pathological changes is also possible.