Thermography system for research and development

Scientists are constantly seeking new methods to solve problems. Infrared thermography systems have already proven to be an extremely valuable tool in solving a wide range of scientific questions and concerns. A thermography system’s non-destructive testing capability makes it an important tool in many research and development applications.

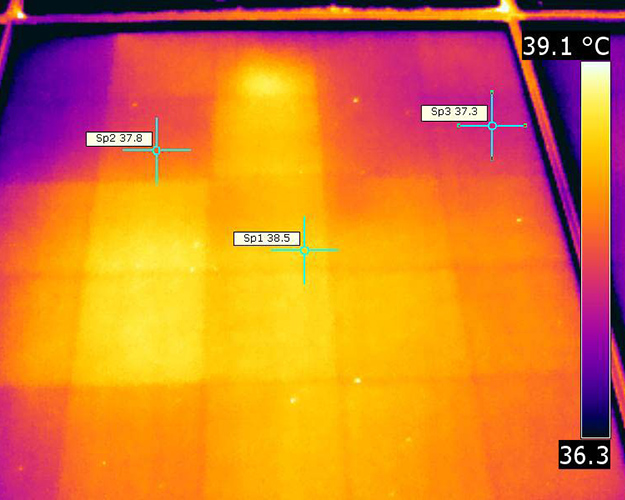

Thermal imaging cameras capture and record temperature distributions, also in real time, to aid technicians and engineers in visualizing and quantifying heat distribution in equipment and processes.

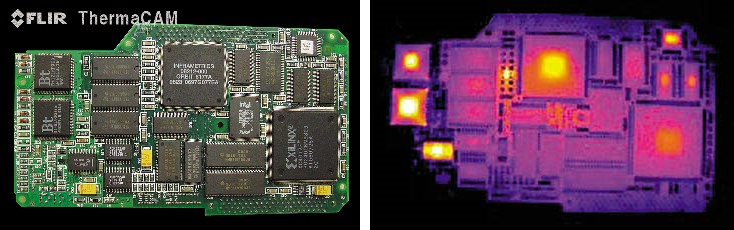

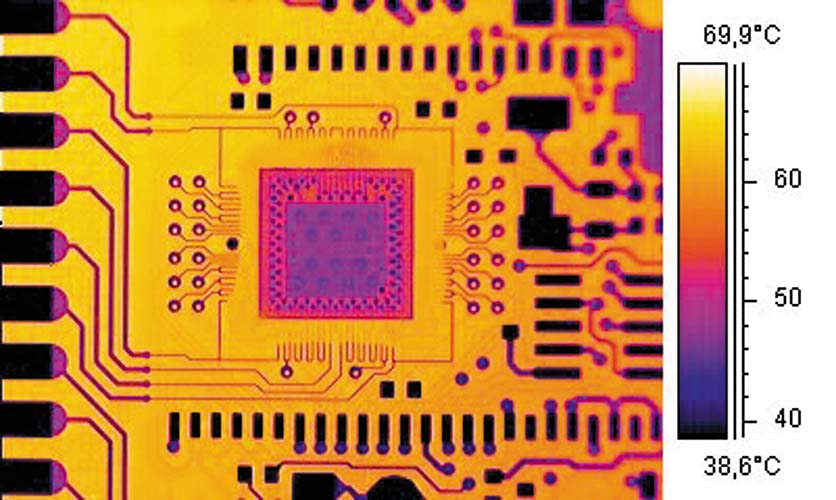

PC board

Advantages of a thermography system:

- Non-contact and non-destructive testing method

- Provides detailed thermal analysis of a situation in real time

- Detects and localizes thermal anomalies

- Saves thermal information

- Enables detailed analysis

Areas of application:

- Microelectronics

- Sports equipment

- Plastics processing, e.g., thermoforming

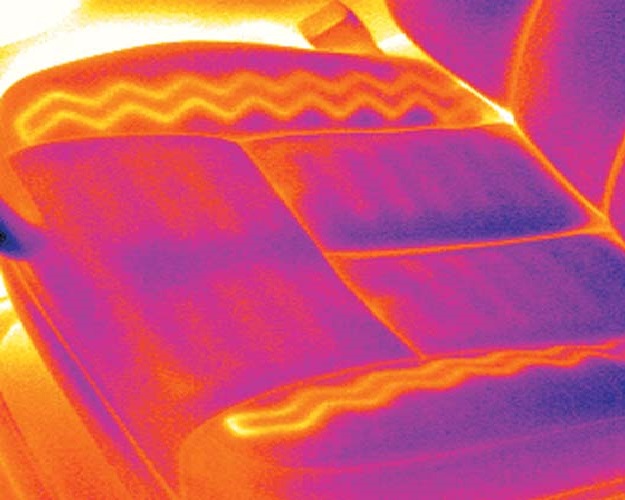

- Automotive industry

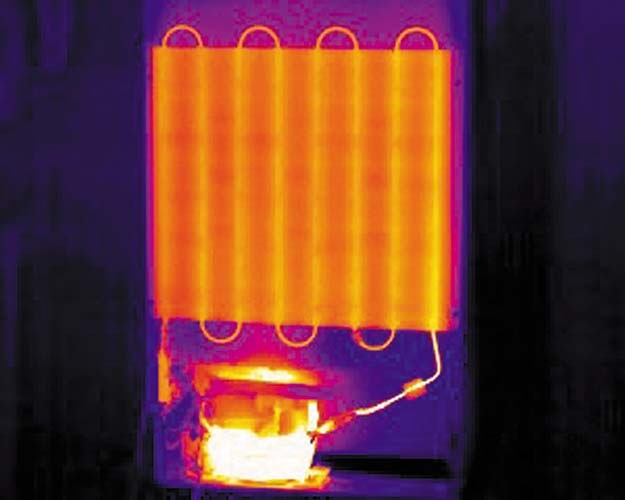

- Appliance design, e.g., household appliances

- Food industry

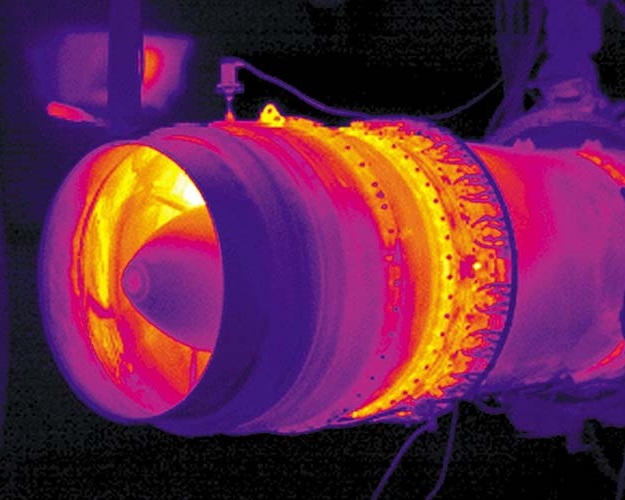

- Material testing and stress analysis

- Product development

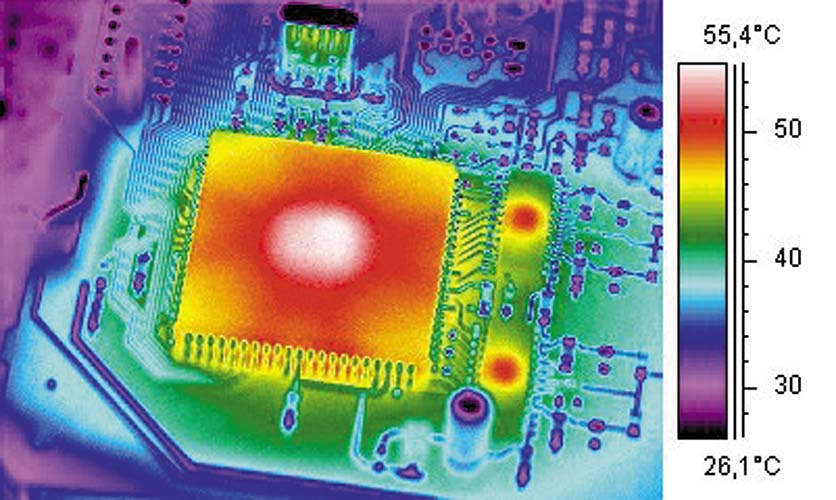

Microelectronics

Diagnostics for electrical circuit boards and microchips

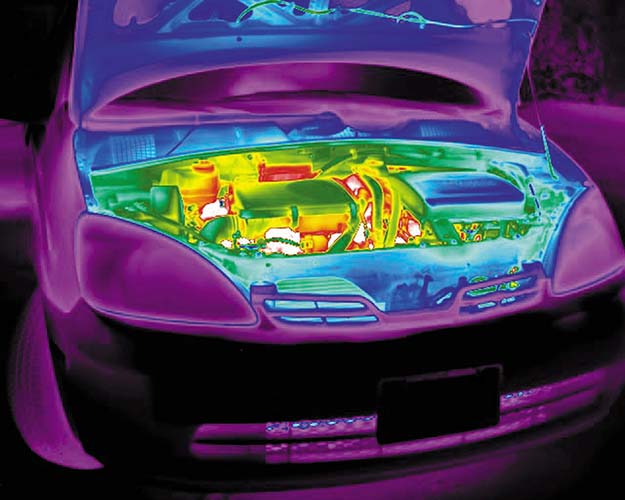

Automotive industry

Motor development

Thermal testing of brakes

Seat heating

Material testing and stress analysis

Household appliances (here: refrigerator)

Load testing an aircraft turbine

Testing / inspection of a photovoltaic system