Cement industry

Fire avoidance in RDF warehousing

Cement industry

Optimum fire protection for refuse derived fuels

Making cement is a costly and a very energy-intensive process. To conserve natural resources and save energy costs, alternative fuels are becoming increasingly important.

It is expected that in just a few years, the cement industry will cover a large part of its energy requirements by using refuse derived or alternative fuels.

Used tires and high calorific fractions processed from waste are often used here. Whatever material is used, it inherently has a high fire load and requires effective early fire detection measures.

Danger due to high fire load

High-calorific refuse derived fuels are usually stored as bulk or baled and produce considerable dust when in loose form. This imposes high technical demands on fire detection. Used tires are dumped or temporarily stored in bulk or shredded form. Their high fire load means that many insurance companies require special fire protection measures.

Loading and conveying processes generate considerable dust placing high technical demands on fire detection systems.

If the flammable materials ignite, in a worst case scenario fire can spread to production and machinery and put the manufacturing process and the very existence of the business at risk.

To avoid damage and production downtimes, fire avoidance and prevention at the earliest possible stage is therefore crucial.

Reliable protection through intelligent hotspot detection

Many refuse derived fuel and cement producers have already experienced the worth of the PYROsmart® infrared fire detection solution for fire avoidance at the earliest possible stage.

PYROsmart® detects critical temperatures within the material (so-called hotspots), even under extreme dust conditions, and therefore reacts much earlier than conventional fire detection systems. With specially developed compressed-air cleaning, PYROsmart® optics are kept free of dust to ensure reliable detection under very dusty conditions.

Overview of advantages

- Quick overview of the monitored areas by video and infrared panoramic imaging (abiroVision® software)

- Early detection of potential fire hazards

- Dependable in dusty environments

- Precise localization of dangerous hotspots

- Fully automatic control of targeted cooling and/or extinguishing

- Minimal use of extinguishing agents and low disposal costs

- Minimization of operational and production downtimes

- Fire-monitor extinguishers can be manually taken over by firefighters at any time (joy-stick control)

- Transparent operation and option for early intervention by organizational fire protection already in the event of pre-alarms

- Complete thermal documentation

- Automatic event recording and alarm forwarding

- Messaging tools for forwarding to responsible persons and personnel

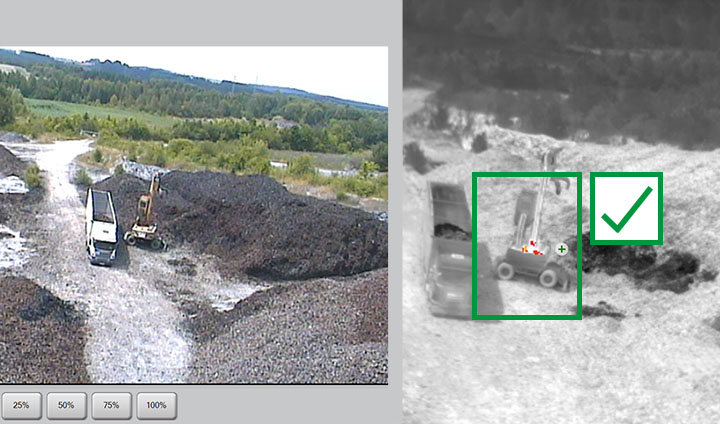

A PYROsmart® pro in weatherproof casing protecting the RDF storage area of a cement plant.

PYROsmart® keeps constant watch over the large area.

Early extinguishing ensures continuous operations

Any critical temperature detected by PYROsmart® is directly reported to a fire alarm control panel. PYROsmart® is able to precisely locate hotspots by knowing the 3D spatial geometry.

The specialized PYROsmart® extinguishing software can then target electronically controlled fire-monitor extinguishers from any major manufacturer and cool or extinguish hotspots.

Targeted extinguishing protects areas unaffected by fire and reduces downtimes. If a fire starts despite early detection, the PYROsmart® extinguishing software automatically controls targeted extinguishing until firefighters arrive and take over extinguishing from outside. Earlier and safer detection is not possible.

Get in contact

A specially developed software algorithm, optimized over many years, differentiates between real fire hazards and everyday heat sources, such as those caused temporarily by vehicles, loaders, etc.

This results in the secure detection of hotspots or fires at the earliest possible stage, as well as in very few false alarms. Operations continue to run smoothly and according to plan.

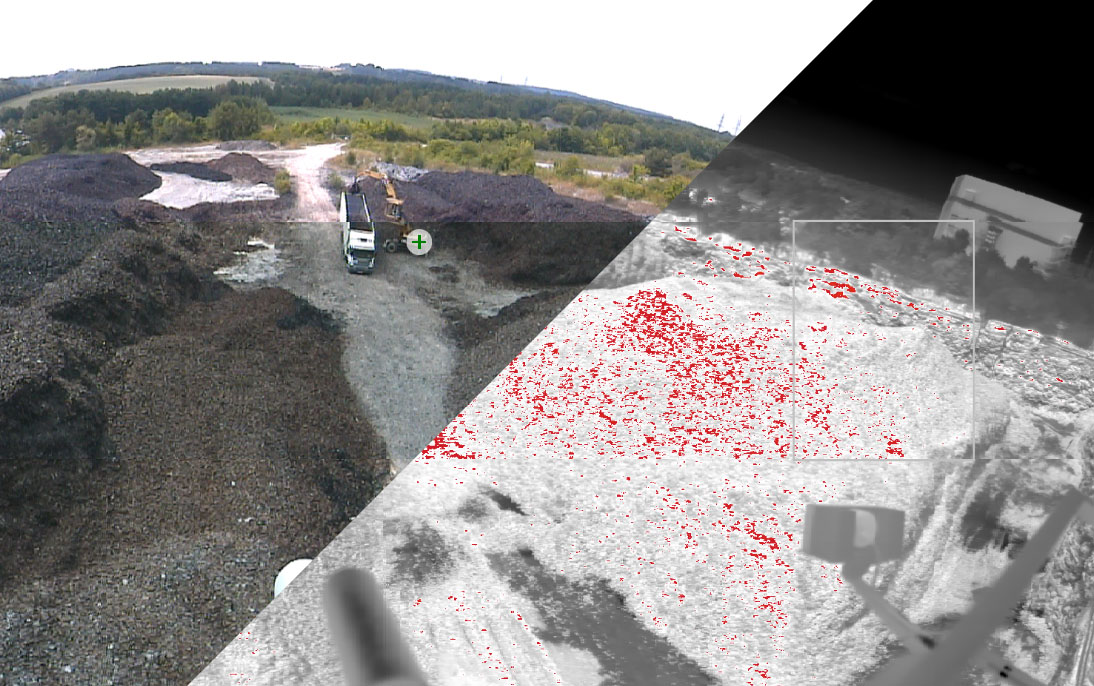

The loading and conveying process of shredded RDF material generates considerable amounts of dust.

Infrared radiation penetrates dusty atmospheres to enable surface temperature measurement under “difficult” conditions. PYROsmart® detects reliably and precisely.

Infrared thermal images are not video images, but instead represent measured temperatures as false-color images. Such portrayals may appear unfamiliar to the human eye.

The PYROsmart® FS pro therefore uses an infrared thermal imaging camera with autofocus function as well as a zoomable video camera including night vision function.

Early detection of critical temperatures is better than fire detection. This makes all the difference in professional fire protection.