Waste incineration

Prevent spontaneous combustion by using intelligent infrared early fire detection

Waste incineration

Waste – a combination of flammable substances

The quantity of thermally recycled waste has been increasing for years, especially in industrialized countries. This is unsurprising considering that waste incineration reduces landfill waste and allows the energy contained in the material to be used to generate electricity, provide heat for processes or as district heat to heat buildings. Despite reusable raw materials being extracted from the waste and sent for recycling, sufficient combustible content still remains in it. As a result, self-combustion of waste is always possible. To compensate for different calorific values, incineration plants usually perform what is known as conditioning, i.e., mixing of the different delivered waste types.

High risk of fire due to spontaneous combustion

Waste is being delivered to incineration plants every minute. Crane operators above the waste bunkers have plenty to do. They use the crane bucket to shift deliveries of different waste mixtures from one waste bunker to another before transferring the combustibles to the furnace in a loader. To optimize thermal utilization, conditioning is performed using a sophisticated stratification system in the waste bunker. This creates stacks and varying loading heights in the bunker. These areas and the mountains of stored material require careful attention when planning fire protection measures and early fire detection, because it is in these areas that fire deterrence and prevention is particularly important.

While flammability is desirable in furnaces, it is a hazard in waste bunkers. Spontaneous combustion of the diffuse mixtures must be expected at any time. The tiniest hotspots can quickly turn into major fires. Early detection of potential fire hazards and thus fire prevention is therefore indispensable for waste bunkers. And this is precisely where the intelligent infrared early fire detection system PYROsmart® waste with its special pan/tilt system has been used for many years.

Dusty, dry, flammable: effective fire deterrence and prevention is essential in waste bunkers.

PYROsmart® waste reliably monitors your waste bunkers. In this example, the system comprises four units and covers the entire bunker area – no point is hidden, thus ensuring precisely targeted automatic fire-monitor extinguishing.

Reliable early fire detection and fire deterrence in waste bunkers

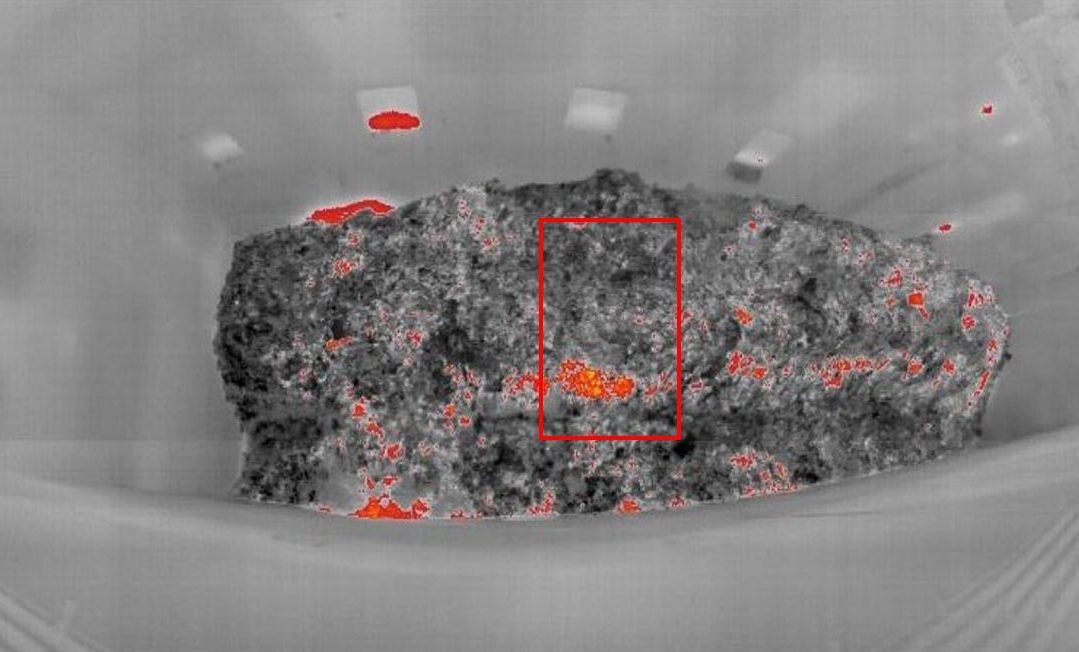

PYROsmart® waste reveals what the eyes cannot see. Heat and warmth. The camera system with a pan/tilt drive and our abiroVision® software enables patented infrared panoramic imaging, so that crane operators always have a view of material temperatures in the bunkers from the cab.

When PYROsmart® waste detects critical temperature that could develop into fires, the system issues an early warning, much sooner than conventional detectors. The crane operator can then take a closer look at the located area using PYROsmart® waste’s video and thermal imaging camera. A detailed overview is gained within seconds, even in poor visibility from dust or smoke. Crane operators can then, for example, quickly remove the critical material and transport it to the furnace.

Keeping the overview: infrared panoramic thermal imaging of a waste bunker. The rectangle shows the currently captured area of the scan. Areas with higher temperatures are color highlighted.

Crane operators get a complete view and can always switch between infrared and video images as well as zoom. For ease of operation, PYROsmart® waste uses touchscreen control.

Automatic targeted extinguishing

When a critical temperature threshold has been reached, the PYROsmart® system can also initiate and control targeted preventive extinguishing using automatically controlled fire-monitor extinguishers.

Targeted extinguishing means that hotspots can be cooled with pinpoint accuracy before a fire starts, and early-stage fires can be quickly extinguished and collateral damage such as long downtimes can be avoided. The specialized extinguishing software can control existing fire-monitor extinguishers from all major manufacturers.

Combining detection and targeted extinguishing takes fire protection to a whole new level for waste incineration plants and waste-to-energy plants. This is what PYROsmart® waste does.