PYROsmart® pro

Technological leader in infrared early fire detection

PYROsmart® pro is the most intelligent system for early fire detection. PYROsmart® pro uses state-of-the-art infrared and video cameras to continuously scan large areas and objects, measure temperatures and create continuous panoramic thermal imaging. Potential fire hazards can then be detected as they develop and before a fire starts. When critical temperatures are detected, the system locates the hotspot, triggers an alarm and reports it to the fire alarm control panel. Automatic precision cooling or targeted extinguishing of the hotspot is also optionally available.

PYROsmart® pro is a pan/tilt system to enable monitoring much larger areas than fixed systems are capable of. The patented abiroVision® software, in conjunction with durable special drive units, enables scanning to be performed with repeatable accuracy for many years to come. This is what makes PYROsmart® so unique.

Conventional fire detectors, e.g., smoke and heat detectors, only respond to the effects of a fire (smoke, heat). Sprinkler systems then extinguish large areas without pinpoint accuracy.

PYROsmart®, on the other hand, promptly detects thermal signatures and hotspots and can instigate precision cooling and/or extinguishing.

Because infrared radiation penetrates dust and smoke, the system also works reliably in such environments.

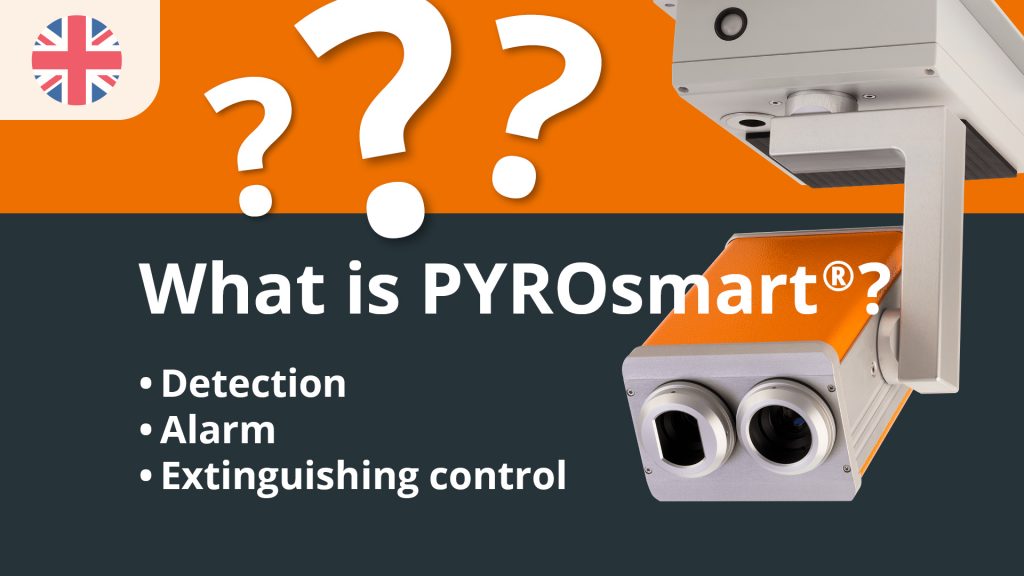

PYROsmart® with a connected fire-monitor extinguisher in a recycling facility.

A PYROsmart® unit under the ceiling of a semi-open facility.

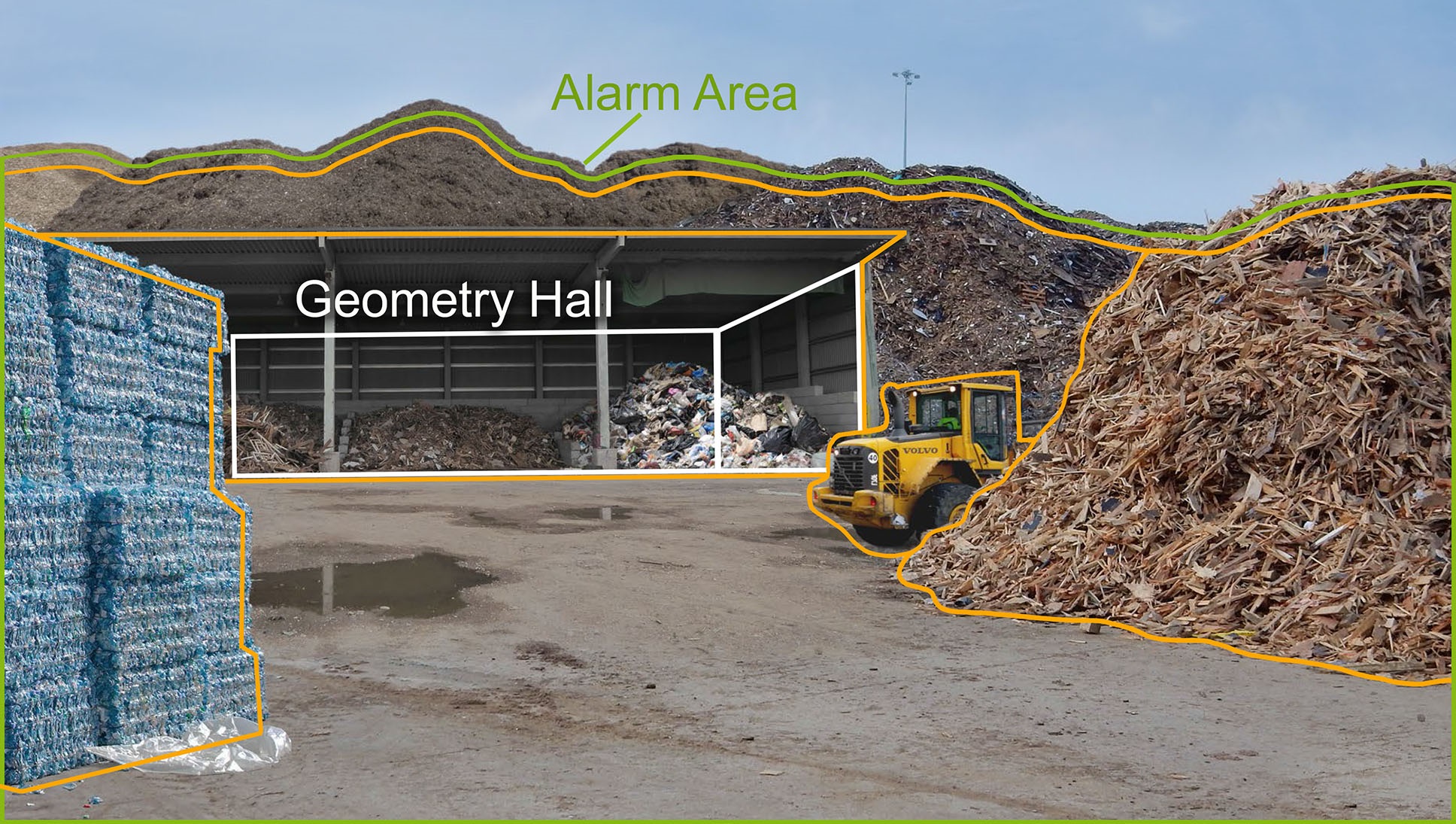

Intelligent fire prevention with precision 3D spatial detection

PYROsmart® understands the spatial geometry of the monitored area and is capable of pinpointing hotspots at any time. Panoramic thermal imaging displayed on a screen are evaluated to enable localization in 3D space.

Normal thermal hotspots, such as hot exhausts from loaders, are identified using sophisticated algorithms and will not trigger false alarms. In practice, this procedure has proven itself to be extremely reliable.

This is state-of-the-art intelligent fire protection.

Automatic targeted extinguishing – controlled by PYROsmart®

Identifying fire hazards is one thing. Actually preventing fire outbreaks is a logical extension of the concept. Our fire protection system excels at doing both. The proprietary, practice-proven PYROsmart® extinguishing software communicates with any extinguisher from major manufacturers and controls targeted extinguishing in the event of an alarm – dynamically adapted and fully automated. Hotspots can then be cooled with pinpoint accuracy before fires start, and early-stage fires can be quickly extinguished and collateral damage prevented.

Advantages of immediate, targeted extinguishing:

- Unaffected areas remain protected

- Operational interruptions are avoided

- No disposal expenses for large-scale extinguishing incidents

- You save time and money

Targeted cooling/extinguishing. Unaffected areas remain protected.

Get in contact

Early detection of critical temperatures is better than fire detection. This makes all the difference in professional fire protection.

Keeping an overview with panoramic thermal imaging

The internationally patented PYROsmart® panoramic thermal imaging (abiroVision®) enables entire monitored areas to be displayed in one view. This makes operation at the terminal easy and intuitive and guarantees quick familiarization with all the necessary functions.

Infrared panoramic thermal imaging in false-color representation. The individual scans are merged into a detailed thermographic panorama image using our patented abiroVision® software.

Advantages:

- Thermal overview of the entire monitored area (e.g., 5,000 m²).

- Immediate localization in the event of an incident because the entire area is depicted.

- The overall image is used for evaluation (intelligent, incident-based evaluation).

- Intuitive menu navigation to obtain a detailed view (clicking on an area in the panorama view instantly shows details of the location).

- Clear signaling and display of messages (alarms, pre-alarms, etc.).

The user interface has been designed to be self-explanatory and can be touch-operated if required. In normal operation only a few, key functions are displayed with settings, etc., being located within a log in area.

This keeps everything clear, structured and focused on the monitored area.

Infrared and video – the best of both worlds

Infrared thermography portrays measured temperatures of the monitored area as a false-color image. Such portrayals may appear unfamiliar to the human eye. The PYROsmart® pro therefore uses an infrared thermal imaging camera with autofocus function as well as a zoomable video camera including night vision function.

- Switching between infrared and video images is possible if required and improves assessing potential fire hazards. Displaying interim levels is also very simple.

- The video camera’s 14x zoom function enables objects to be viewed in greater detail whenever required.

- PYROsmart® pro’s infrared camera with autofocus also makes it ideal for monitoring objects with variable viewing distances (e.g., waste bunkers with fluctuating fill levels).

Robust and durable – even under tough conditions

- Infrared light penetrates dusty and smoky atmospheres, so PYROsmart® is ideally suited for such conditions and can be relied on to detect with pinpoint accuracy.

- Electronics and sensors undergo continuous compressed-air cleaning, so that no dirt enters the device interior ensuring PYROsmart® always provides clear images.

- In the unlikely event of a PYROsmart® malfunctioning, the unit is simple to replace with all settings being automatically transferred.

- An uninterruptible power supply (UPS) means PYROsmart® operates fully independently.

- PYROsmart® can be updated and will therefore remain state-of-the-art for many years.

- PYROsmart® can be maintained remotely at all times. The system can be accessed if there are any issues.

Having trust in yourself is good. Checking yourself is even better.

To ensure continuous protection and maximum security, the system monitors itself and performs regular analyses:

- The integrated PYROcal® calibration source enables regular and independent testing of the infrared measurement accuracy.

- A special module continuously monitors the entire PYROsmart® system, including its infrastructure. This enables long-term monitoring of the system and all its components.

- The self-monitored complete system complies with the planning and setup guidelines of VdS Guideline 3189.

- PYROsmart® pro has passed all VdS device and software certification tests and received VdS equipment approval under number G219023.

Further information on VdS approval [in German]

PYROsmart® is FM Approved

The early fire detection systems of the PYROsmart® and PYROspy® series have been certified according to FM Approval FM3260 since 2024 (Certificate No. FM24US0039).

Increases in surface temperature in potentially hazardous or critical areas indicate the potential development of a fire before fire and smoke are evident.

By promptly detecting these temperature changes, fires can be averted or quickly extinguished.

PYROsmart® detects temperature changes contactlessly with continuous state-of-the-art infrared monitoring (“thermal imaging camera”).

Detecting critical temperatures and triggering alarms takes place autonomously within the PYROsmart® unit.

PYROsmart® can route alarms directly to a fire alarm control panel, trigger further actions and/or control targeted cooling or extinguishing of the hotspot.

PYROsmart® therefore works together with extinguishers of all common manufacturers.

PYROsmart® pro is indispensable wherever flammable materials with high fire loading are stored or processed in large areas or semi-open facilities and where a fire can cause devastating damage very quickly:

- Waste incineration plants / waste bunkers

- Recycling facilities

- Paper industry / paper storage areas

- Cement industry / fuel storage

- Facilities processing refuse derived fuels

PYROsmart® pro – product movies

Systems for your industry:

- Waste disposal and recycling

- Waste incineration

- Paper and pulp industry

- Refuse derived fuels

- Cement industry