Coke quenching in coking plants

Detecting and post-quenching ember hotspots on coke ramps

Coke quenching / post-quenching

Cost savings from optimized coke water content

Not too wet, not too dry, not too cold, not too warm: perfection is required in coke quenching and post-quenching. Too much water in coke increases energy costs in blast furnace processes and impairs process stability. The quality of pig iron quality may also then suffer. Yet too little water can lead to fires on the journey to the blast furnaces. Any damage to conveyor belts might interrupt material flows and drive costs up even further.

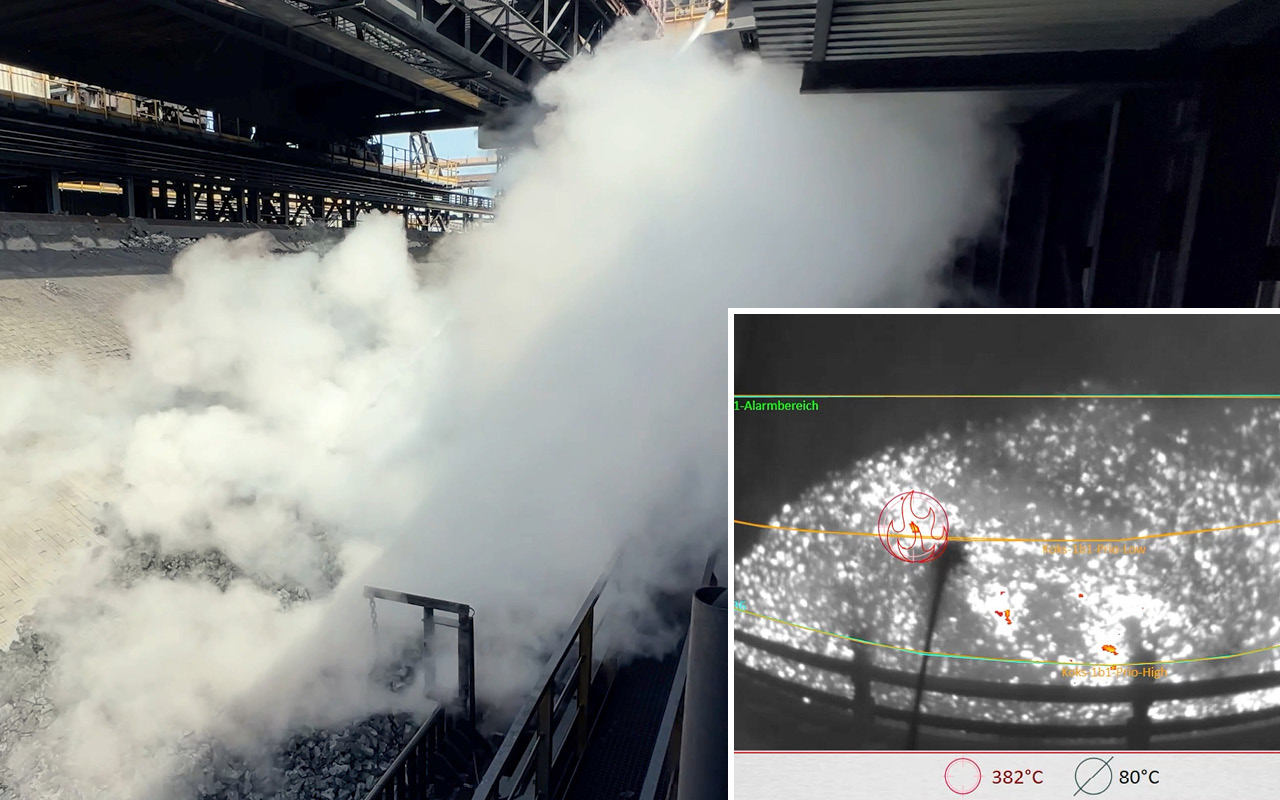

Last but not least, conventional, manual coke post-quenching is a high health hazard. Manual post-quenching is made more difficult by small pockets of embers (“hotspots”) on the coke ramp often not being visible to the naked eye. Steam, smoke or bright sunlight can also impair visibility. Post-quenching is therefore often inefficient with the coke water content then becoming too variable.

Optimizing coke water content is directly linked to cost and energy savings in pig iron production in steel mills. So how can coke post-quenching be improved?

Quenched coke is temporarily placed on a coke ramp. Any residual ember hotspots here require post-quenching.

Smart infrared thermal detection enables precise and fully-automated detection and post-quenching of coke hotspots

PYROsmart® quenches hotspots with minimal water

PYROsmart® is a smart infrared system for temperature monitoring and fire prevention. PYROsmart® uses a high-resolution, high frame-rate infrared thermal imaging camera. PYROsmart® is therefore capable of reliably detecting coke hotspots on ramps within fractions of a second. Thermal detection also means that ember hotspots invisible to the naked eye can also be reliably detected. Locating and sizing of all hotspots takes place continuously with real time updating while the material is under constant motion. PYROsmart® therefore always knows where there’s “fire”.

Then comes the highlight: PYROsmart® targets the quenching and post-quenching of ember hotspots using fully-automated fire monitor extinguishers. Locating hotspots on the coke ramp means the plant can minimize the required amount of water. Quenching only takes places where it is required, according to the principle of as much water as necessary, but as little as possible!

Operating multiple fire monitors is unproblematic. Software algorithms compute optimal quenching procedures and priorities and initiate targeted quenching as quickly as possible. The system continuously adapts and readjusts itself to external conditions and material movements.

The result: the autonomous system quickly and effectively detects and quenches hotspots on the coke ramp with pinpoint accuracy. Risk of damage to conveyor belts is significantly reduced. Water content in the coke is also optimized and stabilized (prevents large variations). The overall result is significant cost savings and more stable operating processes – both within coke plants and in blast furnaces making pig iron.

Reliable coking equipment – even under tough conditions

Infrared radiation penetrates steam and smoke

PYROsmart® keeps watch long after the naked eye is no longer capable. Coke quenching produces large amounts of steam and smoke, but infrared radiation is practically able to penetrate such conditions unimpeded. The infrared image shows the location and current temperatures of ember hotspots. Quenching/cooling thereby happens continuously in a controlled and targeted way!

Steam is generated during coke post-quenching. The quenching jet is clearly visible in the infrared image, as are actual temperatures.

PYROsmart® is low maintenance and functions autonomously 24/7

The system is autonomous and is made up of the PYROsmart® detection system, multiple fire monitors (left in image) as well as an operating terminal and a control center (right in image).

Despite the harsh conditions, PYROsmart® is a low-maintenance installation. The system operates reliably 24/7 and meets all the requirements of state-of-the-art coke plant technology. PYROsmart® has undergone all relevant stress tests in laboratories as well as in practical continuous operation. During standard operation, no personnel are required to be present in the hazardous area.

The detection unit’s electronics and sensors undergo continuous compressed air flushing to prevent the ingress of fumes and coal dust. PYROsmart® guarantees a clear view.

PYROsmart® is upgradable and will remain state-of-the-art for many years with remote maintenance available at any time.

Video – Coke quenching using PYROsmart® at Zentralkokerei Saar GmbH

With the kind support of Zentralkokerei Saar GmbH

Special benefits:

- Cost savings in coal processing by optimizing coke water content

- Prevents downtime from fire damage to conveyors, etc.

- Protects health by eliminating hazardous tasks

Key features of automated coke quenching:

- Safe, fast detection of hotspots on ramps

- Targeted, effective quenching using minimal water

- Stop evacuation in the event of unsuccessful hotspot quenching

- Detects and reports ramp utilization

- Operates autonomously, with low maintenance and in harsh environments

- Quenching software for smart operation of multiple fire monitors

17 years of experience in coke quenching…

… and more than 30 years in infrared thermography!

The fully-automated coke quenching / post-quenching application is based on 17 years of proven experience. Learning, experimenting and improving until achieving the perfect system. Always with the aim of optimizing the coke's water content and making quenching even faster and more precise.

PYROsmart® technology combines hardware and software. Both are under constant development. The PYROsmart® extinguishing software has seen significant development and has been specially optimized for ramp quenching in coking plants. The smart quenching software can also easily operate and combine multiple fire monitors for targeted quenching.