Waste disposal and recycling

Systematic fire prevention for highly dynamic fire loading

Waste disposal and recycling

Your fire protection insurance: early detection and immediate extinguishing

Collect, sort, prepare, process: the recycling industry is more than ever contributing to a sustainable supply of raw materials and recyclables. Recycled raw materials are often an alternative to primary raw materials and are increasingly substituting them completely. There is now very little waste that is actually “disposed of”.

The recycling industry is diverse. While some companies merely collect and pre-separate waste, others specialize in the high-tech processing of waste into pure recycling raw materials. This is where expensive specialized machines are usually used.

Danger due to high fire load

Raw and processed products in recycling are usually stored in piles or bales in close proximity within warehouses or open-air storage facilities. They have a large fire load.

If a fire occurs for whatever reason, it will quickly spread to production and machinery, potentially putting production or even the entire existence of the company at risk. The destruction of the recycled material itself may also represent a considerable loss.

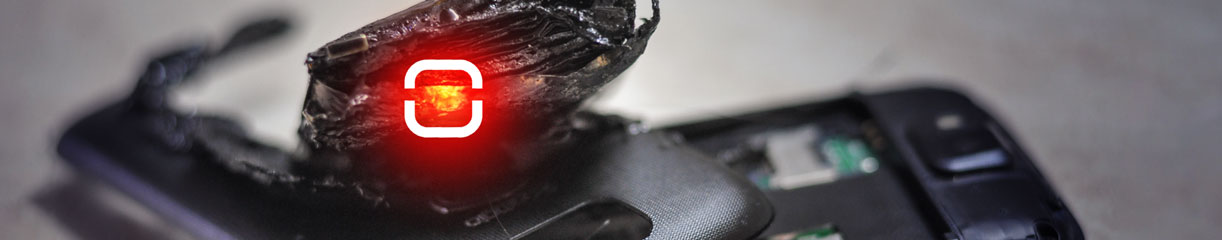

Lithium-ion batteries and accumulators that have been disposed of incorrectly are also a fire hazard at the input areas of recycling plants. These batteries represent a constant danger and can become a source of fire within seconds and at the latest during crushing.

To avoid damage and production downtimes, detecting potential fire hazards at the earliest possible stage is therefore crucial.

Protection using intelligent early fire detection

PYROsmart® is a dependable infrared fire detection solution that is increasingly being used by recycling companies for fire prevention.

PYROsmart® detects fire hazards at the earliest possible stage, both in large outside storage areas, inside buildings and at conveyor belt transfer points.

The principle is a simple one: rather than detecting smoke or fire, it detects critical temperatures, known as hotspots. These occur before a fire starts.

PYROsmart® therefore reacts much earlier than conventional fire detection equipment.

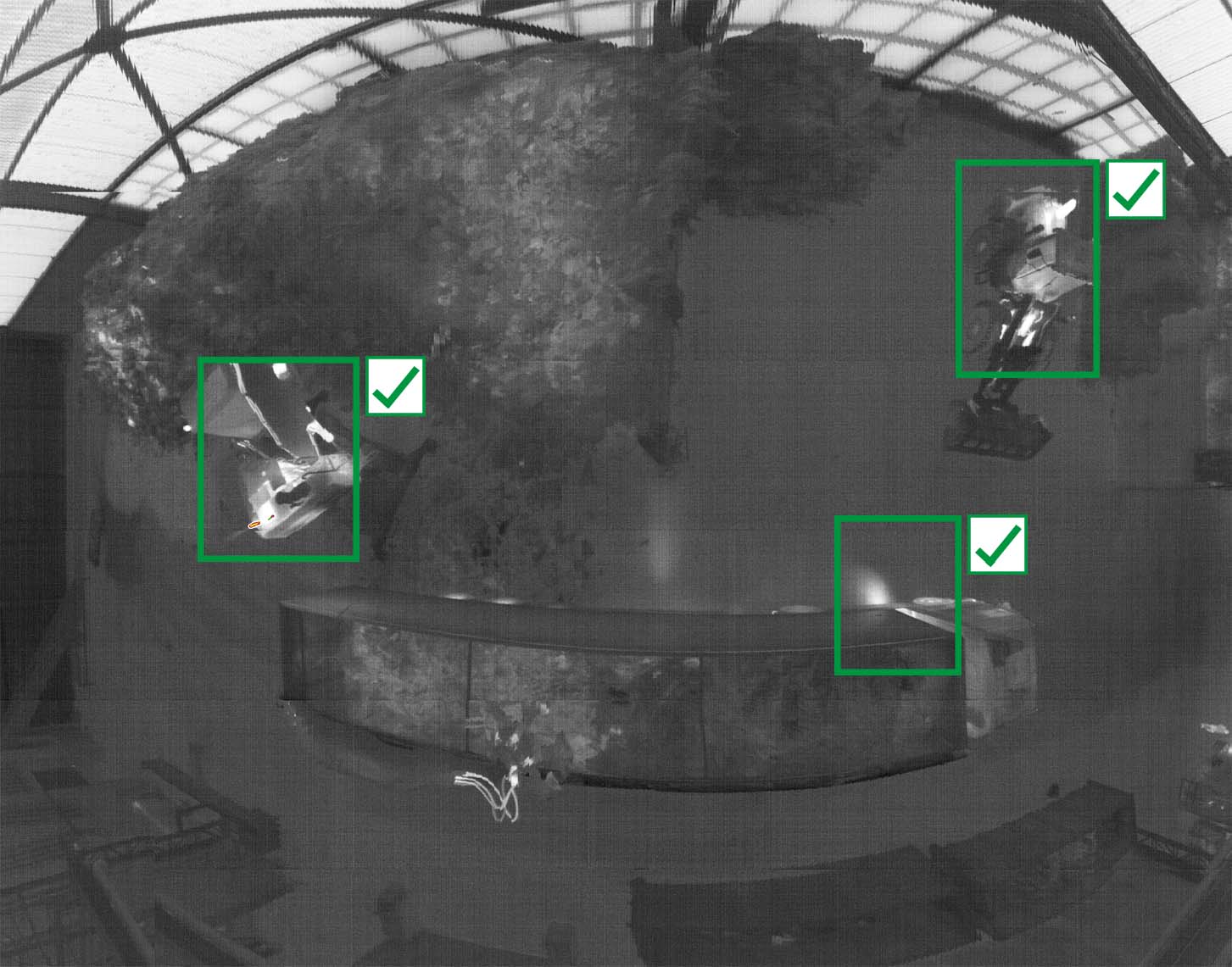

The system can also precisely localize detected hotspots using an area-wide infrared panoramic overview, automatically, 24/7 and for years to come.

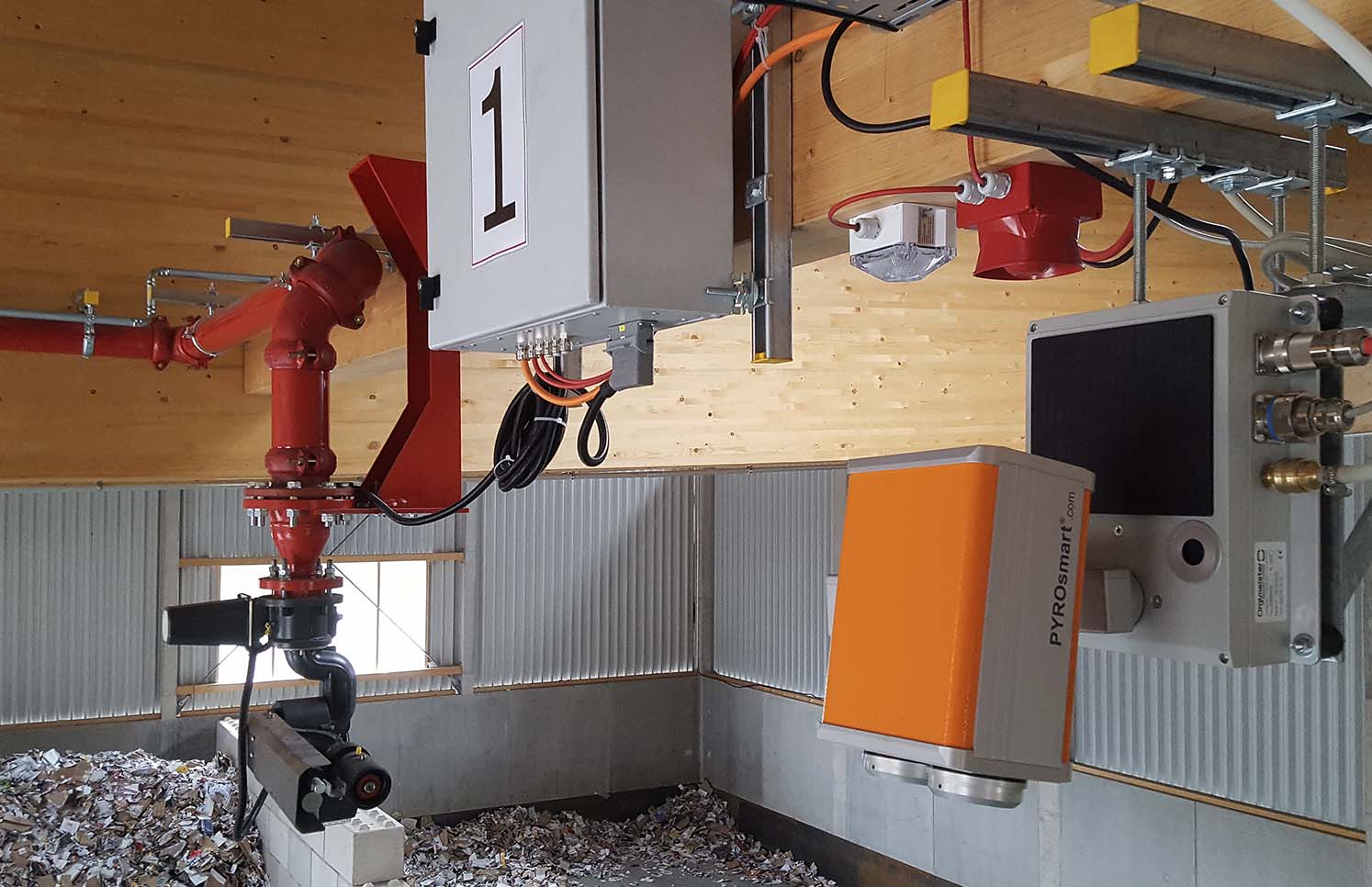

PYROsmart® pro protecting an indoor storage area with neighboring processing line.

PYROsmart® protects waste disposal and recycling operations by preventing fires.

PYROsmart® areas of application

PYROsmart® monitoring the outside area of a recycling plant.

- Outdoor storage areas

- Indoor areas with loose material in chutes and bunkers

- Semi-open facilities

- Dusty bulk storage with combustible materials

- Bale storage

- Processed product storage locations (indoors and outdoors)

- Conveyor belt transfer points conveying highly flammable materials

The non-scanning PYROsmart® one version is ideally suited for monitoring belt transfer points.

“Please never throw batteries or electronic items containing batteries into the bin!”

Why? See for yourself in this video from SUEZ UK / Aberdeen City Council …

PYROsmart® avoids this – by through early hotspot detection and automatic extinguishing. In more than 500 plants worldwide.

Early targeted extinguishing

What is generally more effective, faster and cheaper than large-scale and non-targeted extinguishing is the intelligent alternative: automatic targeted extinguishing.

The specialized PYROsmart® extinguishing software can control electronically operated fire-monitor extinguishers from major manufacturers and cool and/or extinguish detected hotspots in a targeted, pinpoint manner. Targeted extinguishing protects unaffected areas and reduces operational downtimes and production stoppages.

If a fire spreads despite early detection, the PYROsmart® extinguishing software controls targeted extinguishing until firefighters arrive and take over extinguishing from outside.

Combinations of PYROsmart® pro and fire-monitor extinguishers in recycling facilities.

Get in contact

Dependable under tough conditions

Infrared radiation penetrates dusty atmospheres to enable surface temperature measurement, even under “difficult” conditions where other detectors quickly reach their technical limitations in fire detection.

With specially developed compressed-air cleaning, PYROsmart® optics are kept free of dust to ensure reliable detection under very dusty conditions. Regular self-test routines with an integrated test source are used to monitor the system.

Compressed-air cleaning keeps PYROsmart® optics free of dust and guarantees a clear view.

A specially developed software algorithm, optimized over many years, differentiates between real fire hazards and everyday heat sources, such as those caused temporarily by vehicles, loaders, etc.

This results in the secure and automatic detection of hotspots or fires at the earliest possible stage, as well as in very low false alarms. Operations continue to run smoothly and according to plan.

Everyday heat sources from commercial vehicles, etc., are differentiated from actual fire hazards.

Overview of advantages

Targeted cooling/extinguishing. Unaffected areas remain protected.

- Fire prevention through early detection of potential fire hazards

- Precise localization of dangerous hotspots

- Fully automatic control of targeted cooling and/or extinguishing

- Direct line-monitored messaging to a fire alarm control panel

- Quick overview of the monitored areas by video and infrared panoramic imaging

- State-of-the-art messaging tools for forwarding to responsible persons and personnel

- Simple and intuitive operation via touchscreen

- Automatic switching between infrared and video images, panorama view, camera view, all cameras

- Dependable in dusty environments

- Minimal use of extinguishing agents and low disposal costs

- Fire-monitor extinguishers can be manually taken over by firefighters at any time