Predictive maintenance

Thermal imaging has become one of the most valuable diagnostic techniques in predictive maintenance. Thermography using industrial thermal imaging cameras enables detection of irregularities, usually invisible to the human eye, and the need for maintenance measures. It can do this during ongoing operation, without any contact required, and before costly system failures or recourse claims occur.

The FLIR E8-XT industrial thermal imaging camera is easy to operate and covers a temperature range of -20°C to 550°C.

Thermography can be of crucial assistance when planning and implementing necessary measures (e.g., repairs, modernization, etc.).

Benefits to you:

- Lightweight and easy to use industrial thermal imaging camera

- Checks while systems are under load

- Identifying and localizing of problems

- Non-contact temperature measurement

- Time and money saved

- Fire and accident hazards minimized

- Documentation of plant condition and potential risks

- Weakness and damage detected at an early stage

- Improved loss prevention and operational safety

Areas of application:

- Electrical thermography: high, medium and low voltage installations

- Mechanical systems: motors, drives, bearings, pumps

- Pipelines and insulation

- Buildings/Facility management

- Production

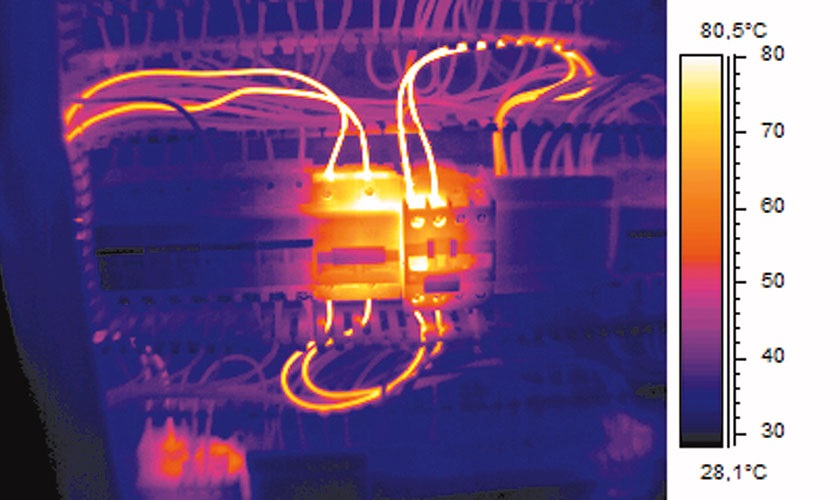

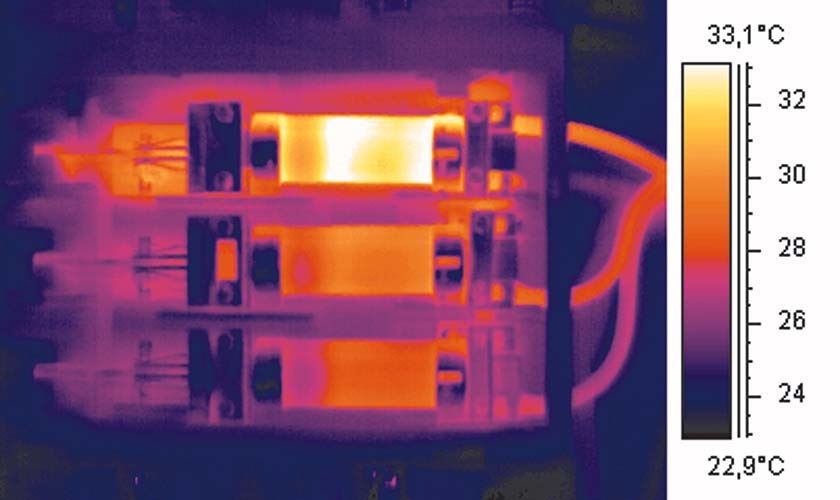

Electrical thermography

Low voltage

Loose or corroded connection

Terminal with high contact resistance

Overload

Fuse damage

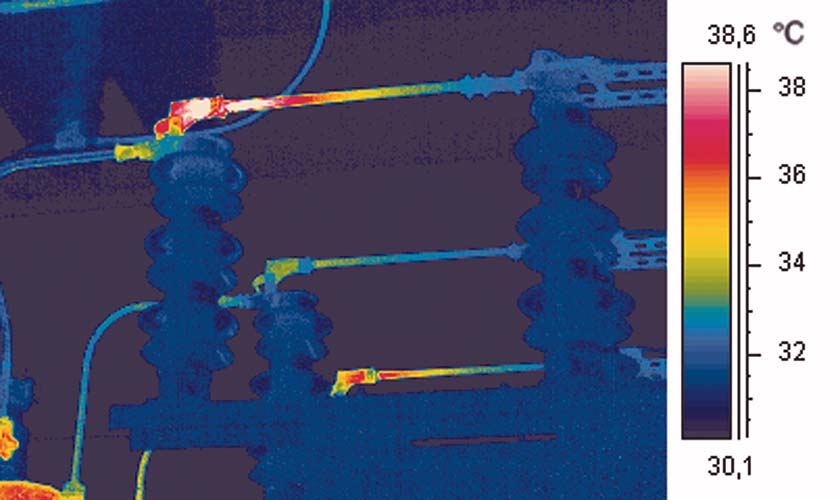

Electrical thermography

High voltage

Incorrectly attached connection

Oxidation of a high voltage switch

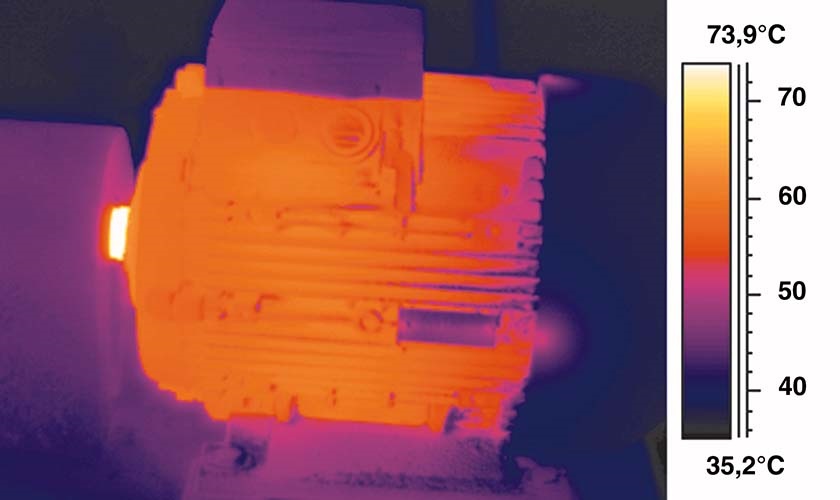

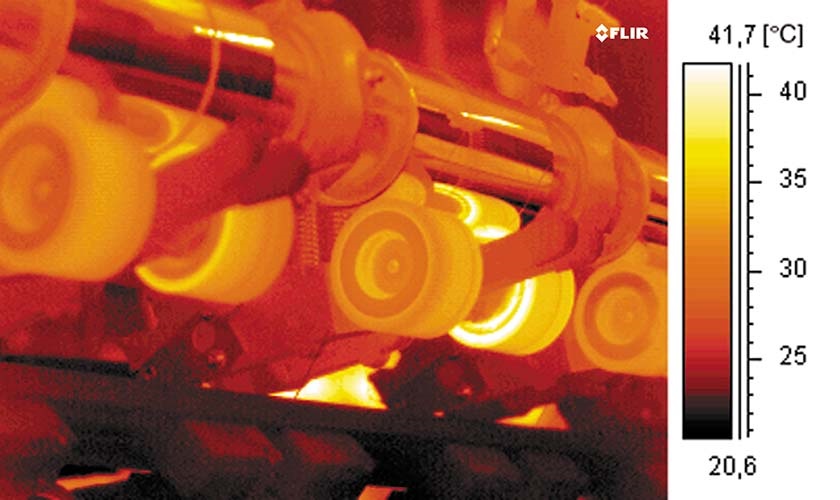

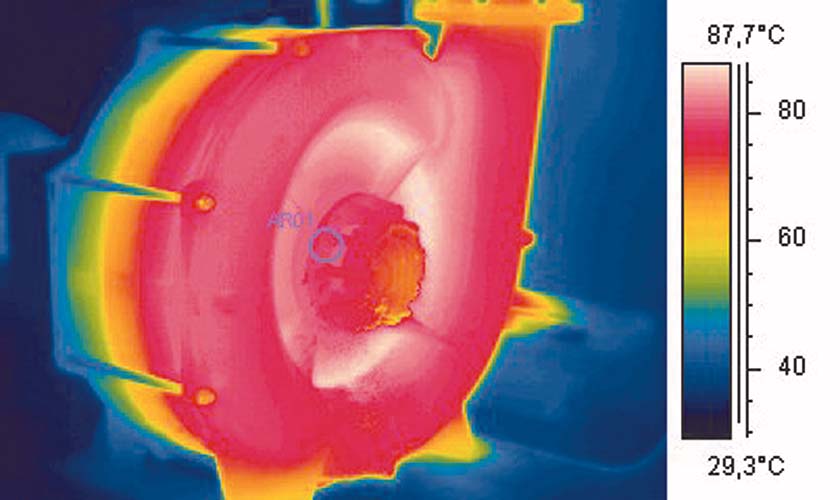

Mechanical systems

Defective drive motor

Irregular roller

Overloaded pump

Overheated bearing shell on motor shaft

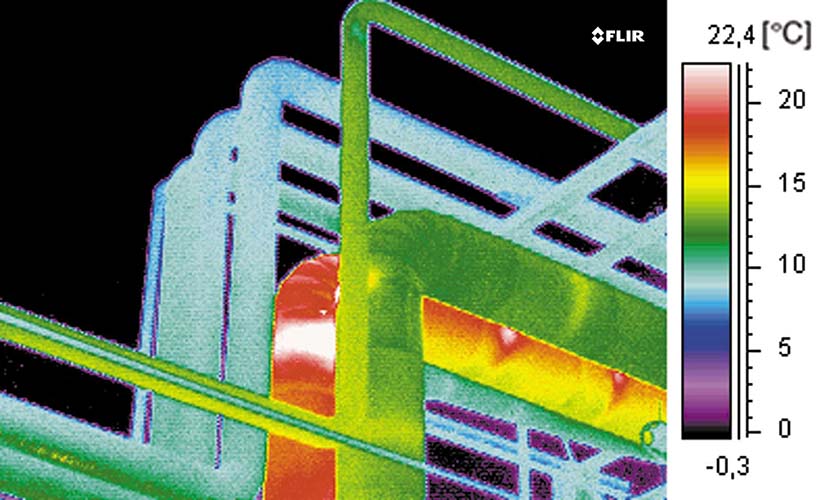

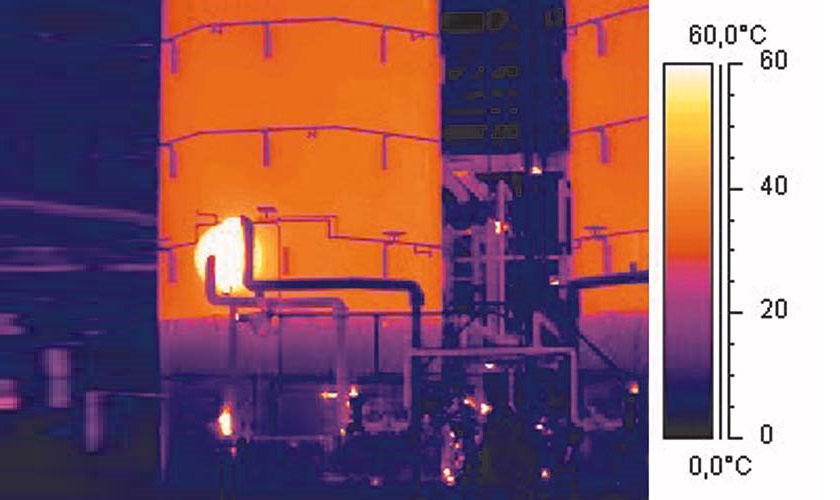

Pipelines and insulation

Sagged insulation

Faulty insulation