Automation

Being able to use automation to ensure quality and prevent and detect fires is extremely important in many industries. The ideal solution is a permanently installed infrared camera that uses infrared measurement technology to monitor processes and systems 24/7 and 365 days a year, and automatically detects even the slightest temperature differences. This way of applying infrared measurement technology is already in use in a wide variety of industrial automation applications around the world.

Thermal imaging cameras enable cost-effective, fully integrated thermography and measurement systems for a wide range of applications such as process development and optimization, industrial process monitoring, product testing, quality assurance, security applications and fire protection.

A thermal imaging camera can even detect minimal temperature differences under the most adverse operating conditions, such as the presence of smoke, fog or steam in the measurement environment. Examples:

Process monitoring using infrared measurement technology

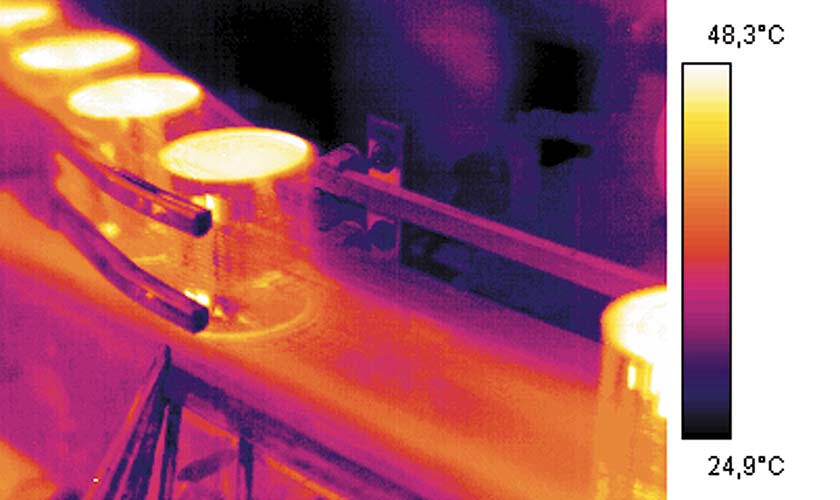

Bottle filling