Building thermography

Using a thermal imaging camera enables precise analysis of a building’s thermal weakness. Building thermography helps in targeting insulation measures and ultimately in saving energy costs.

The FLIR E8-XT thermal imaging camera provides exceptional thermographic details and is the perfect tool for diagnosing building defects.

Benefits to you:

- Easy to use thermal imaging cameras and evaluation software

- Fast and non-contact measurement

- High reliability and flexibility

- Meaningful and verifiable output for customers

Areas of application:

- Locating thermal bridges – visualizing heat losses in buildings

- Energy saving analysis (energy consultancy)

- Locating leaks

- Air tightness testing

- Pipeline damage

- Heating, ventilation and air conditioning

- Quality control and construction monitoring: building, insulation, roofing work, windows

- Real estate evaluation

- Damage prevention

- Investigating damp that can lead to mold growth

Identifying energy losses / detecting construction defects

Building thermography is an efficient, non-destructive method of revealing potential construction defects. This enables targeted planning of remediation measures.

A book recommendation [in German] on the topic: Leitfaden Thermografie im Bauwesen (external link)

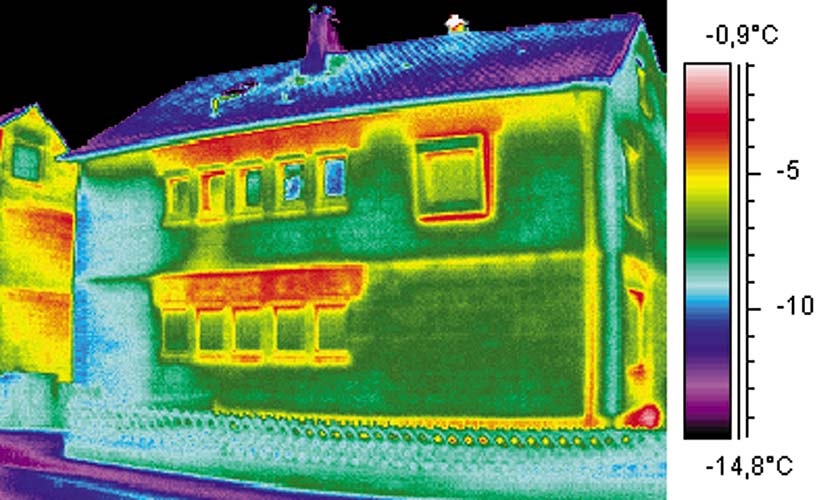

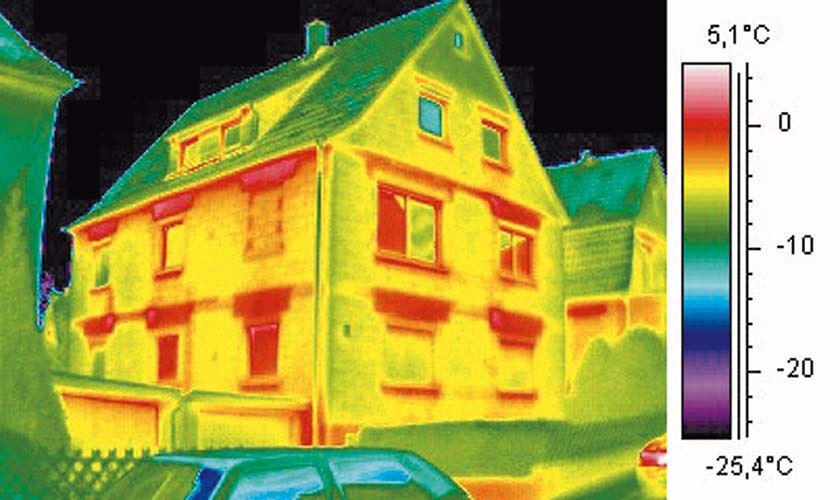

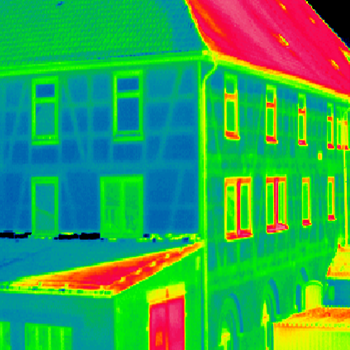

Comparison: with and without full thermal insulation

Classic thermal bridges

Classic thermal bridges

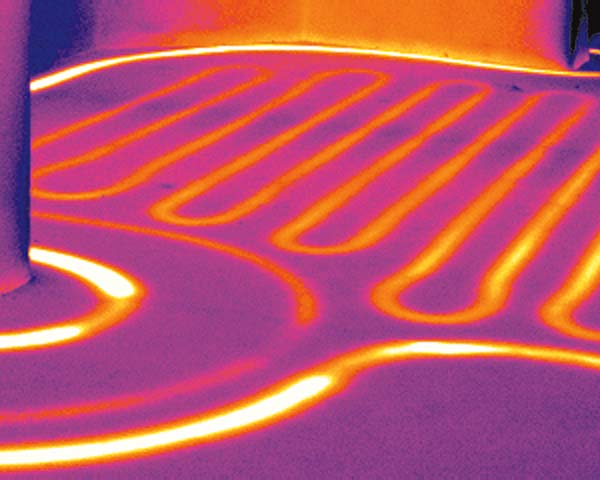

Locating leaks

Thermography performs well in locating and checking pipelines and pipeline leaks, even if the pipelines are under floors or behind plaster.

Location and length of underfloor heating

Ventilation, heating, air conditioning

Building thermography makes it simple to check the functioning of air-conditioning, radiators and room ventilation systems. The obtained information can, for example, be used to plan seating areas and workstations.

Defective flue

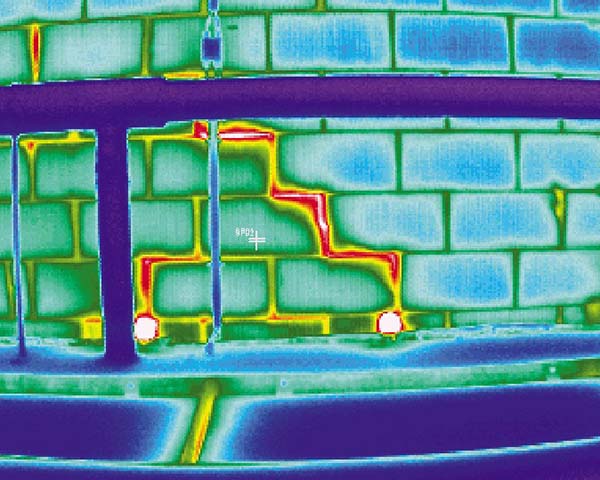

Building renovation

The timber framework is visible under the rendering

Thermography provides valuable information when renovating or converting buildings.

It is an important tool in heritage conservation, for example, to detect timber framework concealed under rendering. Measures needed to conserve the structure of the building can be initiated in good time.

Thermography reveals brickwork under rendering

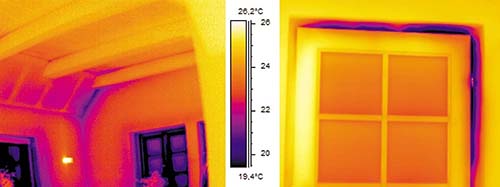

Air tightness testing using thermography

Air tightness in a building can be tested using the blower door method. A blower installed into a window or door opening creates negative pressure in the building.

Cold air enters the building at points that are not airtight. A thermal imaging camera can then be used to locate the areas. Smoke or fog is therefore not required.

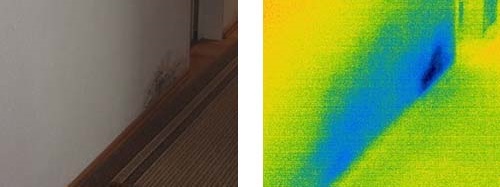

Early prevention of mold infestation

Where thermal bridges exist, condensation from room air may occur inside a building. Minerals in walls and wallpaper provide ideal breeding grounds for fungal spores.

Mold infestation and the associated risks to occupant health can then arise. Thermal imaging cameras can be used to instantly pinpoint critical areas.

Damp flat roofs

Locating dampness and leaks in flat roofs is a further application for building thermography. Using a thermal imaging camera, the extent of dampness can be detected and localized non-destructively, quickly and cost-effectively.

Checking drying procedures

Thermography can be used to check the progress of drying measures, e.g., for sodden screeds or walls. Thermal imaging helps to efficiently optimize drying times.