PYROsmart® one

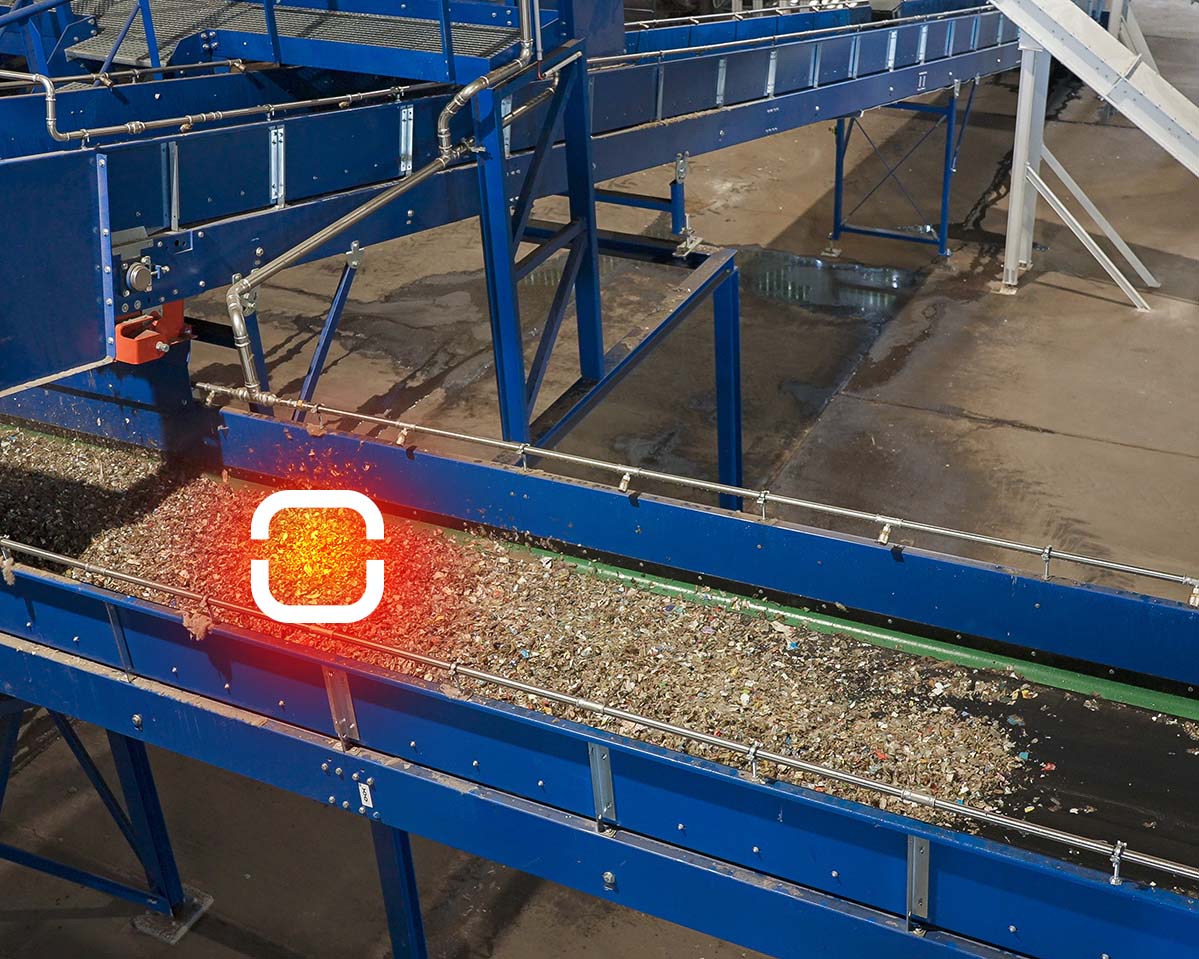

Infrared early fire detection for small areas and conveyor systems

PYROsmart® one is the system of choice for infrared temperature monitoring of objects that can be viewed at a fixed distance and within a fixed image section. Examples of such objects are small areas, systems and transfer points on conveyor belts. The unit uses a fixed-focus, high-resolution infrared camera for detection, with the angle of view optimally matched to the application by using different lenses.

PYROsmart® one is VdS certified and FM Approved!

Conventional fire detectors, e.g., smoke and heat detectors, only respond to the effects of a fire (smoke, heat). Sprinkler systems then extinguish large areas without pinpoint accuracy.

PYROsmart®, on the other hand, promptly detects thermal signatures and hotspots and can instigate precision cooling and/or extinguishing.

Because infrared radiation penetrates dust and smoke, the system also works reliably in such environments.

PYROsmart® one detects critical temperatures in free-falling material.

PYROsmart® one performs detection autonomously and is connected to the fire alarm control panel via monitored alarm outputs.

Belt monitoring

Temperature monitoring of free-falling material and belt transfer points provides significant benefits. At these points, material gets turned over and comes into contact with oxygen. Any hotspots here can therefore become particularly warm/hot. If they had previously been concealed by overlying material, they will also only be detected here.

PYROsmart® one protects against fires breaking out by quickly detecting any hot materials and hotspots entering the plant and thereby preventing fires from happening.

PYROsmart® one always keeps belt transfer points in view.

PYROsmart® one instantly activates hotspot cooling (here: water mist nozzles) in the event of an alarm.

The PYROsmart® principle: fire prevention through temperature monitoring and targeted extinguishing

By monitoring increased temperatures, PYROsmart® one can detect potential fire hazards at an early stage – before a fire breaks out. Its special infrared thermal imaging camera with high measurement repeatability rate ensures complete reliability over many years, also on fast moving conveyor belts and at belt transfer points.

When critical temperatures are detected, the system triggers an alarm, reports it to the fire alarm control panel, and stops the conveyor. Automatic cooling and/or extinguishing of the hotspot is also possible as an option, e.g., via water mist nozzles on the belts.

Early detection of critical temperatures is better than fire detection. This makes all the difference in professional fire protection.

Instant detection and independent alarm triggering

With fast-moving volumes of material, hotspots require split-second detection. There is no time to lose. PYROsmart® one therefore uses an infrared thermal imaging camera with an extra-high measurement repetition rate (“frame rate”). This ensures that the system never misses a detail. The compact device performs the evaluation itself making this step lightning fast.

Alarm triggering and the optional direct control of different extinguishing systems takes place independently of any operating or control computers – another plus in matters of security.

The video shows infrared detection in free-falling material in real time.

Robust and durable – even under tough conditions

- Infrared radiation penetrates dusty and smoky atmospheres, so PYROsmart® one is ideally suited for such conditions and can be relied on to detect with pinpoint accuracy.

- Electronics and sensors undergo continuous compressed-air cleaning, so that no dirt enters the device interior ensuring PYROsmart® always provides clear images.

- In the unlikely event of a PYROsmart® malfunctioning, the unit is simple to replace with all settings being automatically transferred.

- An uninterruptible power supply (UPS) means PYROsmart® operates fully independently.

- PYROsmart® can be updated and will therefore remain state-of-the-art for many years.

- PYROsmart® can be maintained remotely at all times. The system can be accessed if there are any issues.

Embers entering systems is a common cause of fires.

Conventional spark detection systems only detect glowing particles with high critical intrinsic temperatures, whereas PYROsmart® detects low hazardous temperatures and very small “hotspots” – also when they are moving at speed.

If critical temperatures are detected early, a fire outbreak can be avoided.

Detecting critical temperatures and triggering alarms takes place autonomously within the PYROsmart® unit.

PYROsmart® can relay an alarm directly to a fire alarm control panel, stop the conveyor and control targeted hotspot cooling or extinguishing, for example, via water mist nozzles on the conveyor belts.

A key feature of PYROsmart® one is the focus of the monitored area on a fixed defined surface. The system is therefore being used for infrared temperature monitoring of small areas, systems and belt transfer points, for example, in:

- Recycling facilities

- Facilities processing refuse derived fuels

Do you need to thermally monitor larger areas, for example, entire facilities? PYROsmart® FS pro comes into its own here.

Get in contact

PYROsmart® one – product movies

Systems for your industry:

- Waste disposal and recycling

- Waste incineration

- Paper and pulp industry

- Refuse derived fuels

- Cement industry